However, I reserve that all the information that will be provided in these articles has been obtained by me alone and is not the origin of any leak. So if you always complain about the content of my articles, I apologize, but in specified a situation you request to better defend any delicate information. At the same time, I besides point out that any speculation may be imprecise.

So let us decision on to the first article

-------------------------------------------------------------------------------------------------------------

However, it is not worth going consecutive to a simple, direct answer. specified an answer is frequently imprecise and at the same time can mislead. Therefore, it is better to break the full issue down into factors.

|

| Badger Infantry Truck - photograph HSW |

|

| Indicative cut of front armor bwp Puma |

|

| Bwp AS21 Redback hull without additional armour |

The ricocheting of anti-tank missiles is simply a substance known to those curious in the secondary war. The improvement of subcalibre ammunition (especially 1 with prolonged cores) has reduced the frequency of this phenomenon, but this process has not been eliminated. It's just that the angles of the bow of the armor at which this phenomenon occurs have changed. In the case of full-caliber planet War II ammunition, ricochets reached ricochets at an armor tilt of about 55 - 60°, while with modern anti-tank ammunition the required slope is already about 75 - 80°. The exact angle depends on the thickness of the metallic plate used, its mechanical strength and the characteristics of a given anti-tank missile.

In the case of Badsuk, this refers to the usage of advanced hardness armoured steel plates, the thickness of which is most likely 10 mm. For the advanced armor plate, the angle of its slope is about 80°. It is precisely due to the fact that for specified an angle there is simply a higher probability of ricocheting an anti-tank projectile than if the same plate were tilted at an angle of 65 to 72°, we could talk about optimizing a lump of an intermediate armored armored armored vehicle.

But what kind of missiles can ricochet specified a heavy inclined armor plate?

Here, judaic designers from Plasan Sasa came to the aid, who tested this phenomenon for a 25 mm subcalibre APDS anti-tank missile. This kind of ammunition continues to usage the tungsten core or (better) uranium, but is characterized by a smaller ratio of the core dimension to its diameter. In this case, M791 missiles were utilized for the study, which until the mid-1990s were the primary anti-tank ammunition in American bwp M2 Bradley and wheeled armored transporters LAV-25. However, these are lighter missiles than Swiss PMB 073 missiles, which by 2012 were the mention kind of anti-tank ammunition for the verification of level 5 ballistic protection according to the STARAG 4569 standard.

|

| Anti-tank missiles 25 x 137 mm (top): M791, PMB 090 and M919 The list lacks PMB 073 - not produced since the late 1990s. |

|

| Visualisation of M791 ricochet on 8 mm thick steel plate (hardness: ~500 HB, angle of inclination: 81°) |

3UBR6 is simply a full caliber anti-tank rocket with a 400 gram steel core. This rocket was designed to overcome simple metallic (steel or aluminum) shields with a tiny angle of inclination (for steel up to 30°). The projectile itself officially pierces a 26-millimeter steel plate (probably ~300 HB) inclined at an angle of 60° at a distance of 300 metres. However, its effectiveness falls importantly erstwhile the mark is protected by simple spatial armor or more advanced composite shields. Taking into account the usage of the steel core and the low output velocity (970 m/s), it is likely that the biggest problems will gotta overcome composite shields containing ceramic layers. But I'm going to discuss this more thoroughly with another armored bullet.

Furthermore, authoritative data do not mention the ability to penetrate tilted shields at an angle of more than 75°, suggesting that, despite the usage of the 3UBR6 ballistic cap, it is simply a ricochet-like missile.

|

| 30 mm kind 3UBR6 anti-tank missile |

The second of the Russian anti-tank missiles - 3UBR8 - is an APDS (Armour Penetrating, Discarded Sabot) subcalibre rocket utilizing a 222 gram tungsten core. It is characterized by the anticipation of penetrating a tilted (at an angle of 60°) steel plate with a thickness of 27 - 28 mm with a distance of 1000 meters. This is simply a much better value compared to 3UBR6 steel. It is besides a comparable value to the American M791, which pierces a 45 mm vertical steel plate from a distance of 1000 metres (which translates into the anticipation of penetrating a tilted steel plate with a thickness of 28 mm). However, this is worse than the Swiss PMB 073, which can pierce a 30 mm tilted steel plate from the same distance.

|

| 30 mm kind 3UBR8 subcalibre anti-tank missile |

However, the Russian maker gives a steel armour penetration value of 35 mm / 60° for a distance of 1000 metres. specified a value may be actual if it results from the usage of NATO-based MIL-STD-662 standard to find the permeability of the projectile alternatively than the Russian standard. The Western standard requires determining armor penetration for 50% of shells (that is, in fact, the average), while the Russians find armor penetration for 75% of cases. Therefore, the values for russian anti-tank ammunition may be undervalued. However, if the maker has not included this in its advertising brochures, it simply gives the incorrectness in this case. Furthermore, the value declared by him himself for 3UBR8 is, in fact, higher than that of APDS kal ammunition. 23 and 25 mm, but it is inactive lower than the penetration of APFSDS kal. 25 mm, which includes Swiss PMB 090 (now mention rocket for level 5 STANAG 4569) and American M919 (using uranium core).

|

| Polish subcalibre anti-tank ammunition. 23 mm Photo by MESKO |

In order to penetrate the armor at all, the impact velocity of the anti-tank rocket must be higher than the limit velocity resulting from the relation between the protective material characteristics and the penetrator material. This is not due to the thickness of the protective material (if not very thin), but to its impact strength (i.e. hardness) and its density, as well as the hardness and density of the material from which the penetrator is made. In case the bullet does not exceed the limit speed, it is mushrooming. This effect is most frequently seen for lead shells, which is due to the fact that lead is simply a very soft metal.

However, we have a somewhat different situation here due to the fact that the materials utilized are much tougher ceramics and tungsten alloy. nevertheless - given an example - in the case of silicon carbide-based ceramics (SiC) the limit velocity for tungsten is as much as 1200 m/s. However, in the case of steel due to its lower density this value is even higher. Comparing this consequence with the outlet speeds of 3UBR6 (970 m/s) and 3UBR8 (1120 m/s), it can be expected that the problem of mushrooming penetrations on ceramic shields may affect them. However, it must be remembered that the limit velocity depends on the material utilized and thus, for example, the corundum (Al2O3), which has a lower hardness than SiC, will have a lower limit velocity value. On the another hand, the problem with the exit velocity may affect all Russian mid-caliber anti-tank missiles, which is due to the construction of the ammunition utilized for high-speed cannons (the size of the casings, the material utilized for them, as well as the characteristics of the propelling material). besides in the case of a long-bore cannon of high-speed kal. 57 mm for its fresh anti-tank ammunition (APFSDS) marking 3UBM22 is expected to exit velocity around 1190 m/s.

|

| The impact of the limit velocity on the penetration of ceramic armour by an elongated tungsten penetrator. The limit velocity for this case was previously estimated at 1210 m/s |

|

| Anti-tank circular 30 mm BR type |

- 9-A-4543, which is an APCR-type aircraft missile, besides utilized in Russian combat helicopters

- 3UBR7, which would be a (mythical) variant of the 3UBR8 rocket utilizing the uranium core,

- 3UBR10, which is simply a variant of the 3UBR6 rocket with polymer leading rings (their aim is only to reduce barrel wear, which takes place at the expense of the life of the projectile itself),

- 3UBR11, which is an APFSDS kind anti-tank missile,

There are besides indications of the existence of a kind 3UBR9, but it is not known what kind of rocket it is. However, it is worth mentioning a small bit about a 3UBR11 missile.

|

| 30 mm kind 9-A-4543 |

The main problem with russian anti-tank missiles utilizing the steel core is their low efficiency in overcoming spatial shields or utilizing strong slope. While for the above mentioned 3UBR6, the critical angle of the armor can be estimated at about 30°, for rifles, anti-tank missiles can break as shortly as the armor is beaten at an angle of 18°. The hardness of the material utilized - especially armoured steel - besides influences this phenomenon. Here the effect is best seen utilizing advanced hardness steel, starting with class 500.

|

| Fragmentation of B-32 anti-tank firearm shells 12.7 mm (left) and 14.5 mm (right) After passing through a thin, tilted steel plate. The plate on the left was 4.4 mm thick and on the right - 5 mm thick |

The basic standard utilized for ballistic protection tests of light and medium-armoured combat vehicles is the standard STANG 4569 (also known as AEP-55) introduced in 2002. Its 3rd variant is presently in force, which was implemented in 2014, but in its case the changes in the ballistic opposition test are sufficiently cosmetic that in this case the second version of 2011.

According to this standard, six levels of ballistic protection are distinguished, where the highest level provides immunity from subcalibre anti-tank ammunition. 30 mm. However, there is simply a clearly defined explanation of the results in the norm, which may lead to gaps in describing the actual protection of armoured vehicles. This, on the another hand, may lead to a decrease in the effectiveness of passive protection by entering it as a level of protection according to that standard.

In this case, there are 2 problems with standard 4569:

- deficiency of a level of protection to defend against ammunition 12.7 x 99 mm and 12.7 x 108 mm

- 30 x 165 mm ammunition protection is provided within level 6

The STANAG 4569 standard has been "constructed" so that data safety levels consistent with this standard can theoretically warrant protection against all types of ammunition. Therefore, within Level 1, protection against 7.62 x 51 mm firearm shells with lead cores is required, while protection against the armored missiles of this caliber is required within Level 3. In between them - as a level 2 base - protection is required against anti-tank ammunition fired from automatic rifles. The full list of exact and theoretical requirements for each level of protection is given in the table below.

|

| Requirements for ballistic protection according to STAG 4569 Ed. 2 |

In short, we don't usage another standards, due to the fact that we have a standard of 4569. It's time for CS.

Fortunately, there is simply a little-known German standard in the European Union that describes the opposition to both individual armor and passive armor of combat vehicles. It is simply a standard of VPAM-APR 2006, which was implemented on 13 October 2006. Its 3rd amendment is presently applicable, which has been in force since 14 May 2009. According to this standard, there is simply a level of 13 and 14 ballistic protection, which guarantees immunity against ammunition 12.7 mm and 14.5 mm. However, the requirements for these levels of protection are more excessive than the standard phase 4569.

|

| SWISS P anti-tank missile caliber .338 Lapua Magnum |

For this reason, the implementation of the German VPAM standards may be beneficial for the Polish arms industry. It can make greater usage of the possible of 12.7 mm and 14.5 mm ammunition for ballistic tests, while at the same time introducing greater freedom to usage test ammunition.

The second problem with 30 x 165 mm ammunition is that only 3UBR6 kind steel projectile was allowed for usage according to STANAG 4569. More specifically, his Slovak copy is now produced in NATO, making the Russian first not allowed to be tested according to this standard. The main problem with this projectile is that it is characterized by a much lower penetration than NATO-wst ammunition of 30 x 173 mm APFSDS type. And yet both missiles were aligned within 1 and the same level of ballistic protection.

In addition, there is simply a stupid mistake in the average state. The standard specifies that armor gathering the level 6 requirements must defend against ammunition 30 x 165 mm fired from a distance of 500 meters. However, the velocity of impact on the mark (which is 810 m/s) for the Slovak copy 3UBR6 corresponds to a distance of 750 metres. This could mean that NATO has identified a weak, full-caliber anti-tank rocket 40 years ago as a greater threat to their armored vehicles than modern, western sub-caliber ammunition.

There is besides the 3rd problem of this standard, which is frequently carefully overlooked. The requirements for each level of ballistic protection are further geared within levels between 3 and 5. This is because:

- level 3 is the highest level of protection, which requires opposition against hits from a crucial tallness (e.g. in urban fights, the opponent is located in a tall building)

- Level 4 is the highest level of protection which requires opposition against hitting perpendicular to the side and rear of the armored vehicle. In addition, in this respect, a given level can be met if both the sides and the rear of the vehicle are protected.

- Levels 5 and 6 are enforced only by hitting the front of the vehicle or its sides, but at an angle not exceeding 30° from the vehicle symmetry axis

This together means that a combat infantry car which is protected:

- in front of kind 3UBR6 and 30 mm kind 3UBR8 anti-tank missiles,

- on the sides in front of 14.5 mm-caliber anti-tank missiles, and possibly 23 mm-caliber 3UBR1,

- at the rear before 12.7 mm anti-tank missiles

actually meets the requirements for level 4 phase 4569 for front armor and level 3 phase 4569 for protected areas of combat vehicle.

Why is that? I'll remind you again in a nutshell.

Anti-tank ammunition of types 3UBR6 and 3UBR8 is characterized by worse armor penetration from 25 x 137 mm APFSDS kind ammunition. It is so possible that the shield will halt the Russian kal missile. 30 mm, but it won't halt the western kal missile. 25 mm. In this case, this shield meets the requirements for Level 4 (resistance against large caliber firearm ammunition) alternatively than Level 5 or 6. At the same time, level 4 is the highest level of protection of sides and rear combat vehicle. That means the side armor can halt the kal missile. 23 mm or even 30 mm, but it will inactive be marked as gathering the requirements for level 4. On the another hand, the 360° level of protection must be ensured on both sides and back. If the side armor stops the 14.5 mm cal bullet (corresponding to level 4), but the rear armor will no longer halt it, then the armor is marked as gathering level 3 requirements (resistance against tiny caliber anti-tank ammunition) alternatively than level 4.

Without the aid of computer simulations (or the usage of Badger in war conditions) we will never truly know what protection the successor of BWP-1 actually guarantees. investigating shields utilizing non-normative anti-tank means costs, and with limited resources for development, the manufacturer's primary nonsubjective is to quit unnecessary costs associated with working on his product. Instead, we are dealing with the definition of levels of protection that do not truly specify the actual protection of Borsuk against anti-tank weapons.

Besides, the military itself does not require specified additional tests from the manufacturer. Otherwise, specified a request as protection against Russian ammunition. For 30 mm would be determined by the military. An example of a decision with an additional request are ballistic protection requirements for a fresh Czech infantry combat car. It is not only essential to defend against anti-tank ammunition. 30 mm, but besides before Russian anti-tank ammunition. 57 mm. It is actual that the penetration of both types of ammunition is akin (due to the obsolescence of larger caliber ammunition), but that specified a request has been created, it must be enforced from the maker and verified. Furthermore, specified a request as protection against 3UBR6 missiles can be verified by purchasing a single fast-shooting cannon utilizing 30 x 165 mm ammunition and the usage of anti-tank ammunition from Slovak production, which is produced there on the basis of documentation provided by the russian Union in the mid-1980s. Be even by utilizing the air cannon and specially modified ammunition of a given type.

Another word of digression - the above data does not necessarily mention to Borsuk. That's why it's time to present what it might look like in his case.

The basic and overall most crucial information is that Borsuk's plan primarily uses advanced hardness armour steel (class 500) in the form of 10 mm thick plates.

I managed to measurement this thickness on the technology demonstration presented on MSPO 2017, which was later rebuilt to the function of the first prototype. This is important, that in the case of a separate construction of a technology and prototype demonstrator in the former, it is not essential to effort specifically for the thickness of the individual elements of the hull, as it is intended to execute only a visual function in the demonstration itself. Moreover, Badger on MSPO 2017 was deprived of additional buoyancy modules that appeared a year later. This is due to the increase in the mark mass of the combat infantry car, which was initially expected to be 25 tonnes and yet increased to 28 tonnes, while it was essential to keep the same water mobility. This, however, allowed me to accurately measurement the thickness of the outer armor plates. It is besides worth mentioning that the same steel plates (and of the same thickness) are utilized for the production of Opal III, which is present in the Polish Army in the form of artillery command wagons in self-propelled artillery squadrons armed with self-propelled Krab cannons and a single SMG120 Rak mortar, which serves in the Toruń Artillery and Armoured Training Centre. It may be suspected that specified a decision may consequence from reasons of saving money in the improvement of Borsuk and its subsequent serial production.

As far as the supplier of this steel is concerned, this is simply a secondary issue from the point of view of ballistic resistance, since specified armoured steel with a hardness of ~500 HB must meet the requirements of the American MIL-DTL-46100 standard. At least that is the case for most armored steel, as I will discuss in the next article in this series. This makes it possible to use:

- Swedish ARMOX 500 armour steel, which is entirely imported into Poland,

- Finnish armoured steel Miilux PROTECTION 500, which is heat-treated and mechanically operated in the Miilux plant in Tarnowskie Mountains,

- Polish armored steel ARMSTAL 500, which is produced in the Quality Steel Huta in Steel Wola - the direct neighbour of HSW,

- or possibly another Polish armored steel MILAR 480, for which Huta Częstochowa was responsible

However, unlike Rosomak, HSW is not convinced to usage Polish armoured steel in its products, deciding in return to import armoured steel from Sweden. On the another hand, MILAR 480 steel is not produced in series due to financial difficulties of Huta Częstochowa. Unofficially, however, due to problems with fresh steel investors, Węglokoks and PZZ were besides to be offered for 1/6 of its value. The very usage of Class 500 steel is unique to our reinforcement industry. In the West, for the construction of combat vehicles, the class 450 steels are used, which is better balanced between its hardness and plasticity, and at the same time is easier for welding.

The standard 46100 itself is public, so we can find the ballistic opposition of specified a single armor plate. However, due to the requirements of this standard, armor opposition is tested at an angle of 30°, while the consequence itself means a minimum compliant rocket impact velocity at 50% hits. In the case of a 10 mm thick plate, this velocity exceeds the output velocity for the M2 cal. 7.62 mm anti-tank rocket (.30-06 Springfield), which means complete protection against this kind of projectile. However, for the M2 anti-tank rocket 12.7 mm (.50 BMG) the minimum impact velocity is 652 m/s, corresponding to a distance of 550 metres.

Let us now decision on to the issue of the steel armor strategy utilized in Badger. In this case, 2 pictures will aid in the explanation of the text - 1 of my photographs made on MSPO 2018 and the another published in the monthly Military-Technik- Defence Report. My photograph will aid describe Borsuk's side armor, while the photograph from Altair will aid describe the front armor of this combat vehicle.

|

| Photo of the bwp Borsuk body published in monthly RWTO (No. 9 / 2020) - photograph by Marcin Deptula |

However, specified a shield will besides be able to defend the armored vehicle from anti-tank ammunition. 23 and 30 mm utilizing steel cores. This is surely ensured in terms of crew and landing protection due to the fact that this is separated from the drive compartment by additional steel plates. It is simply a disputed issue, but it is likely to supply specified opposition without hazard of harm to the drive compartment. The warrant of failure to harm the engine or another components of the drive, on the another hand, does not be in case of usage against the 3UBR8 Badger with a tungsten penetrator. This may not have been taken into account due to the fact that the STARAG 4569 standard allows the dismantling of the powerpack and another components of the vehicle not being elements of the armor for ballistic tests.

As far as the advanced front armor is concerned, it can be noted that the steel structure is no different from what the Badger looks like. It can so be suspected that the advanced armour consists of a single steel plate with a thickness of 10 mm ~80°. As I mentioned earlier, specified a evidence can not only halt the ammunition of the kal. 14,5 mm, but besides ricochet APDS kind ammunition. 20 - 30 mm. In this area, it can be protected from 3UBR8 missiles without taking into account additional factors. Additional anti-slip layers, which are present on the top plate, may paradoxically have a affirmative effect on Borsuka's anti-slip resistance.

Why was Badger not tested to meet the requirements of Level 5 of STARAG?

2. utilized in the Polish Army undercalibre missiles of kal. 23 mm may be counted as equivalent (but not equivalent) to APDS kal. 25 mm. Today, however, immunity from APFSDS kal-type missiles is required to meet level 5. 25 mm with greater penetration.

3. In case of powerpack dismantling for Borsuk ballistic tests, it may not meet the level 5 requirements.

|

| Bok of the Bwp Borsuk demonstrators - photograph by Piotr Zbies You can perfectly see the individual armour plates and retardant foam |

|

| Cross-section of the side armor of the bwp Borsuk demonstrators. The plate of 8 mm thickness was located outside the vehicle. |

- 12.7 mm fired at right angle from 100 meters

and

- 14.5 mm fired at an angle of 30° at 200 meters

It is known, however, that in the case of 14.5 mm projectiles specified ballistic protection can be achieved at 50% of the hits even erstwhile fired from a distance of 100 meters at an angle of 20°. However, given the usage of the spatial system, where steel plates are 80 mm apart, the actual effectiveness of this armor may be even higher. The above results are possible erstwhile the distance between steel plates is 30 mm.

However, due to the Gestapo's reservations regarding the width of the Badger, which was 340 cm and not 320 cm, as originally decided by the manufacturer, the plan of the side armor of the fighting infantry car was changed. This is rather a clever game erstwhile it comes to intelligence security, but the summarum details of the side armor plan could not have changed much.

The main changes that can be seen are the greater thickness of floats, which can improve the effective protection of the spatial armour and the presence of another thin, tilted steel plate, which can improve the opposition to firearm ammunition hits and increase its likelihood of crushing during penetration.

However, in the case of anti-tank ammunition protection from fast-shooting 23 and 30 mm guns, the opposition to hits shall be based at least 60° for the time being.

In the case of 30 mm 3UBR6 caliber missiles, Borsuk's side armor may be suspected to defend against hits at an angle of 60° at a distance of 500 - 700 meters and at an angle of 65° at a distance of 300 metres.

On the another hand, a kind 3UBR1 23 mm projectile fired at a distance of 700 metres is characterized by a 1/4 lower penetration of steel armor than a larger 3UBR6 projectile. On the basis of this, it can be assumed that the side armor protects against 23 mm hits at an angle of 60° with a distance of 250 - 300 metres.

A completely separate issue is besides the anticipation of utilizing a composite additional armor. At this point, this problem goes beyond the current possibilities of describing this problem. For it is up to both the military and the maker to find whether the Badger will receive heavier additional armor, what additional armor it will be, and how well it will protect. There are a fewer national extra armor proposals, and I hope to describe them all someday. curious producers from abroad who want to propose their solutions in Badger may well appear. The full issue of the usage of additional armor is discussed further in the article.

A completely different communicative is to supply ballistic protection for an unmanned combat tower. Since it is not crewed, it did not seem essential to supply adequate armor at first. For this reason, the first unmanned towers were open-type structures, i.e. structures de facto without their own hull. However, due to the vulnerability of specified towers to weather conditions and harm from branches, stones, etc., the closed-type unmanned towers were gradually implemented for sale and service. Since we are talking about unmanned towers, their armoring remains a secondary issue. due to this, there are not many structures in the planet whose passive armor provides opposition exceeding level 3 around the tower, not to mention reaching level 5 or 6 in front of the tower.

|

| Photo of the ZSSW-30 tower body published in RWTO monthly magazine (No. 9 / 2020) - photograph by Marcin Deptula |

|

| Panzer cover of the old kind commander during ballistic trials |

|

| Cross-section of the old panorama of the commander at ZSSW-30 |

|

| Visible layer of Dyneema in the rear viewfinder cover |

|

| Unmanned tower and close-up to visible (left) bright ceramic component on the tower - photograph HSW |

|

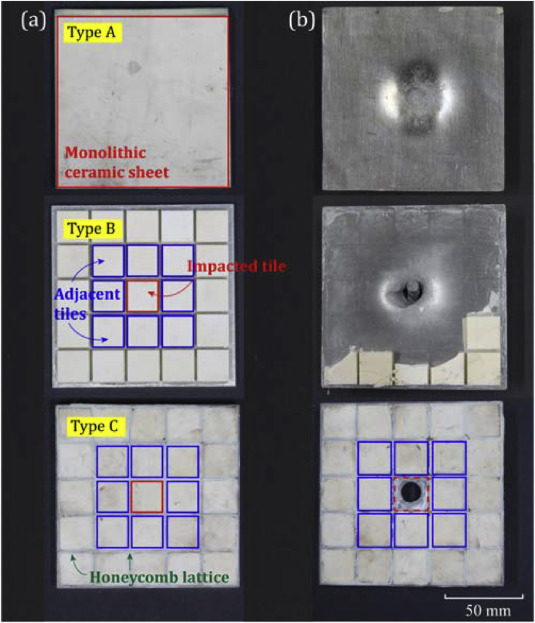

| Comparison of the size of corundum layer harm after hitting 7.62 mm From the top: 1. large, single ceramic plate 2. Ceramic tiles with empty gaps between them 3. Ceramic tiles in aluminium honeycombs |

|

| Potential ceramic armor cut to ZSSW-30. The layout is devoid of frames, fugs, or absorbent layers, which makes its effectiveness questionable. It is besides distant from the 1 shown in the patent. |

The fundamental issue that is forgotten in the context of the Badger is that it was designed as an armored vehicle utilizing modular armour kits. This means that depending on the customer's willingness and needs, this vehicle can be adapted to a given level of ballistic resistance, including opposition to anti-tank grenades with ERA. You can besides manipulate the width of "bewup". In the base version (i.e. without additional floats) Borsuk is only 320 cm wide, which makes it 1 of the fewer caterpillar combat vehicles that are located in the Czech rail gauge (maximum vehicle width: 329 cm). At the same time, with our transport capabilities, you can increase its width to 355 cm or up to 400 cm. Railway wagons intended for the carriage of dense military vehicles were designed to carry tanks from the T-72 family, which are 355 cm wide, even the rail gauge in our country allows the carriage of vehicles up to 4 meters wide.

Paradoxically, however, Borsuk's buoyancy could have another benefit. In addition to utilizing modular armour kits, it would be possible to adjust the "bewup" to the installation of interior peculiar armor modules. This is an different issue in the case of combat infantry vehicles, and not many primary tanks usage specified facilities. However, it cannot be excluded that the implementation of specified an option would only be feasible if the Borsuk hull was somewhat redesigned and adapted to specified changes. On the basis of a photograph of the bare Borsuka body, however, it can be suspected that the free space in front of the propulsion strategy is suitable for the function of "pockets" for additional armor.

The second aspect you can manipulate in Badger is its mass. This is usually limited to the strength of the suspension applied. In the case of Borsuk, it was decided to apply hydropneumatic suspension alternatively of an old torsion-based suspension. In this case, 12 Horstman InArm suspension modules of British-German production of Horstmann were used.

|

| Horstmann Hydropneumatic Suspension Demonstrator built on Bradley M2 chassis |

However, the actual scope of this suspension was to be demonstrated with the bwp proposed by BAE Systems in the GCV programme. There, 14 InArm suspension modules were to supply the maximum fighting mass of the vehicle, which was to be up to 76 tonnes. The same suspension is besides presently proposed for M2 Bradley's combat infantry wagons, where 10 suspension modules are intended to supply a burden capacity of up to 45 tonnes. In the case of Badsuk, Horstman's suspension was configured under a combat mass of 28 tonnes. However, the advantage of this kind of suspension is that it interferes to a tiny degree in the construction of the hull of the combat vehicle, especially in the construction of its bottom, while at the same time the process of replacing the suspension modules is simpler compared to the process of replacing the suspension based on torsion bars. In addition, the burden capacity of the suspension can be changed by selecting force in a chamber filled with compressed nitrogen. As can be seen, therefore, there are no limits to the possibilities of the hydropneumatic suspension applied.

The only limit for expanding the amount of armor on our "bawup" is the engine used. The drive unit from Friedrichshafen, which is presently utilized in Borsuk, can accomplish up to 815 hp in another variant. The maximum fighting mass of Borsuka would be 35.9 tonnes, while utilizing the origin from BWP-2 this value increases to 38.8 tonnes. However, this is simply a much higher value than the current Borsuka combat mass, which only shows that if the BWP-1 successor's buoyancy is discontinued, the possible for expanding the mass exists and can be utilized well. Given the current combat mass, which with full equipment is 28 tonnes, we can see that the power supply in the propulsion strategy utilized allows an additional 8 to 11 tons of armor to be added. Of course, at the expense of Borsuk's buoyancy. This adapted Badger could be much better armored, starting with the provision of level 4 STARAG around the vehicle and level 5 for the front armor.

- V. Paris, A. Weiss, A. Vizel, E. Ran, F. Aizik, Fragmentation of armor piercing steel projects upon oblique perforation of steel plates, DYMAT 2012 - 10th global Conference on the Mechanical and Physical Behaviour of Materials under Dynamic Loading, EPJ Web of Conferences, No. 26, 2012

- J.C. LaSalvia, B. Leavey, H.T. Miller, J.R. Houskamp, R.C. McCuiston, Recent results on the fundamental performance of a hot-pressed silicon carbide impacted by a subscale long-rod penetrations, Advances in Ceramic Armor IV, pp. 89 - 97

- A. Weiss, A. Borenstein, V. Paris, M. Ravid, N. Shapira, Evaluation of critical ricochet Englishs for 25 mm APDS-T projectile on metallic targets - modeling and verification, Procedures of the 2019 Hypervelocity Impact Symposium, pp. 82 - 88

- Adam Wiśniewski, Paweł Żochowski, Add-on passive armour for light armed vehicles protection, Weapons Technology Problems, 1 / 2013, pp. 17 - 24

Adam Wiśniewski, Modular layered passive composite armour, patent PL 219768 B1, announced 09.12.2013, granted 31.07.2015

- Peter Zbies, Standard non-comparable - ballistic verification of armor and anti-tank ammunition, fresh Military Technique, 11 / 2020, pp. 38 - 44